Thanks for the bump TheLastMillennial. There has been a lot of news lately! Just finding the time to make a post here, and it's going to be a big one.

~~~~~~~~~~~~~~~~~~~~~~~~~~

THE 3D PRINTING AND KEYCAPS UPDATE

~~~~~~~~~~~~~~~~~~~~~~~~~~

Since the turn of the new year, and the whole month of January, a lot has happened on the TI-84 KE project.

Parts have been coming in slowly, and progress is being made. It is starting to look pretty good!

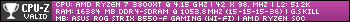

I purchased a new 3D printer to make the cases for the keyboard. The Creality CR10S Pro V2.

300x300x400mm build volume, so large enough to make keyboard cases, model airplane parts, and everything in-between.

Starting out with the calculator motherboard and backlight power switch circuit mounting positions, I printed out test pieces to make sure everything would fit:

Finding a spot to put a reset switch, it took a few test prints to find the perfect fit:

It took a few tries, but the battery compartment is re-created, so the donor calculator's battery cover is reused in the new case.

This allows the original battery to be used, and retains the functionality of the removable battery without increasing the enclosure's thickness:

Combined with the prototype screen bezel, here is the total thickness:

~~~~~~~~~~~~~~~~~~~~~~~~~~

In addition, the keycaps came in from overseas! They are the right colors, and the right quantity. Here are 5 sets in bags, one laid out:

And here are they blank keycaps on the switches/plate itself. The number keys are from a standard keyboard numpad:

They blank keycaps are PBT material DSA profile, ordered from AliExpress. The color is consistent, the only downside is the blue is

slightly darker than expected.

But, you say, blank keycaps would be nightmare on a calculator! The solution: Printing legends using dye sublimation.

With help from you all on chat, I designed key legends for all 51 keys. The legends include the 2nd and Alpha functions.

I ordered dye sublimation prints of the legends from a shop on Etsy, and they arrived at my door in a few days. The navy ended up a bit more purple than blue

.

Heading down to the dollar store, I picked up a cheap hair straightener and a spring clamp. To apply legends to the caps, heat and pressure is applied.

Each legend has to be lined up on the key, held in place with some tape, and then clamped against the key while in the iron for 2 minutes. Here is my setup:

A few layers of cuts from a silicone baking sheet provide padding and even pressure across the whole key. Here are the first row of keys while I perfected the technique:

That first row took me over an hour, and it wasn't that consistent. Finally getting into a grove, and tuning in the heat and timer settings, here is the full set! (3hrs):

So, keycaps can be printed, and the case has come along nicely. I printed a full-size case in black (by chat poll). Putting it all together, here are the current photos:

~~~~~~~~~~~~~~~~~~~~~~~~~~

Major tasks left to do before selling/shipping:

- Solder all electronics together and test everything works

- Re-design the screen bezel for a better fit and easier installation

- Dye-dub the other 4 sets of keycaps (will take about 20 hours)

- Write an instruction booklet/video instructions for assembly of the kit

~~~~~~~~~~~~~~~~~~~~~~~~~~

This project is the largest and most "professional" project that I have ever taken on, and the journey continues to be fun and fulfilling.

I will keep you all updated. Thank you for the encouragement and patience.